2023 (the 19th) China Hot Melt Adhesive Professional Summit Forum

After three-year epidemic period, we are together again for the grand party of Hot Melt Adhesive. On March 21st, the 2023 (19th) China Hot Melt Adhesives Summit Forum hosted by China Adhesives and Tape Industry Association(CATIA) and hosted by Hot melt Adhesives Professional Committee opened at Shangri-La Hotel in Hefei.

With the theme of "Forward-looking Leadership -- Innovative Development of Hot Melt Adhesive Materials", the forum will discuss in depth the technological innovation, stable supply and emerging market trends of hot melt adhesive supply chain, and learn about the latest market trends in 2022 under the impact of COVID-19 and economic downward pressure on industry development. Last year was fraught with uncertainty. Under the influence of multiple factors such as international energy crisis, aggressive interest rate hikes in Europe and the United States, slowing economic growth domestic and abroad, conflicts between Russia and Ukraine, continuous affect of epidemic, Chinese adhesive industry in general faced challenges of high cost and weak demand, but the hot melt adhesive industry still showed strong resilience by relying on its own advantages and characteristics. According to the statistics of the association, the total output of Hot Melt Adhesives in 2022 was 1,431,400 tons, an increase of 8.42% compared with 2021. Total sales were 28.231 billion RMB, up to 15.30% from 2021.

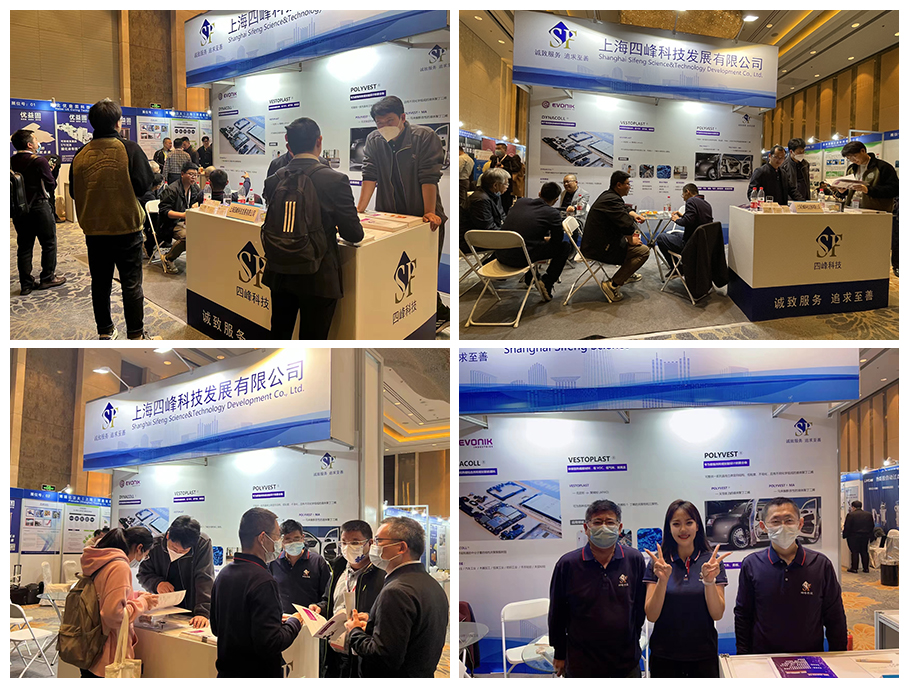

As one of the show exhibitors, Shanghai Sifeng Science&Technology Development Co., Ltd. responded to the theme of the organizing committee and demonstrated the service philosophy of "Sincere Service, Pursuit of Excellence" in this summit forum, providing chemical services and solutions for customers. As the most important exclusive distributor of Evonik Adhesive Business Unit, Shanghai Sifeng Science&Technology Development Co., Ltd. displayed three product series from EVONIK on its booth, Vestoplast®, Dynacoll®, Polyvest®. Meanwhile, as one of the TFS (Together for Sustainability) members, EVONIK launches three GREEN product lines: Vestoplast® eCO, Dynacoll® Terra and Polyvest® eCO.

Vestoplast® eCO are ISCC PLUS certified and sustainable based on a quality balance approach, with over 90% biomass. Vestoplast® eCO significantly reduces carbon dioxide emissions compared to conventional petrochemical feedstocks. Vestoplast® eCO is physically identical to traditional products, allowing customers to easily make the transition from traditional to sustainable products without having to adjust the formula.

Dynacoll® Terra enables customers to produce more sustainable products with a lower carbon footprint through the use of renewable raw materials. Although this water-vapor reactive hot-melt adhesive system is a relatively new adhesive system, due to its remarkable efficiency of energy saving and emission reduction, it has gained widespread attention in the market, and is in high demand in woodworking, textile, automobile and electronic industries.

POLYVEST® eCO is a new line of sustainable bio-based liquid polybutadiene products. Its product line uses sustainable butadiene in production, reducing the use of petrochemical feedstocks by 99.9%. It is certified by ISCC PLUS in the EU like Vestoplast® eCO, and has the same physical and chemical properties as traditional petroleum-based products. Customers can replace directly.

Enjoy the booth scene from Shanghai Sifeng Science&Technology Development Co., Ltd.: