EVONIK POLYVEST®

For more than 50 years, Evonik´s Coating & Adhesive Resins Business Line has been offering POLYVEST®, a range of stereospecific, low viscous and unsaponifiable liquid polybutadienes with different chemical compositions.

Based on their characteristic microstructure, all POLYVEST® grades exhibit an excellent reactivity and can be used for a broad variety of applications. The unsaturated polymer backbone of all POLYVEST® grades offers the opportunity for various crosslinking options, like sulfur curing and oxidative drying. In addition, the functional moieties of POLYVEST® HT and POLYVEST® MA provide further options for crosslinking and make polymer modification feasible. Due to its rubberbased nature, POLYVEST® ST is perfectly suited as a reactive plasticizer in tire and mechanical rubber goods applications.

BENEFITS AT A GLANCE

- Low viscosity

- Excellent chemical resistance to acids and bases

- High water resistance

- Excellent electrical insulation properties

- Low temperature flexibility

- Low moisture and oxygen permeability

Related products

No data

POLYVEST® PRODUCT RANGE

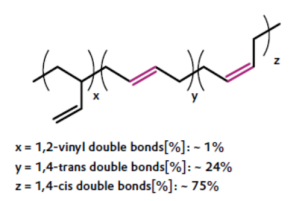

POLYVEST® 110 - non-functionalized liquid polybutadienes

POLYVEST® 130- non-functionalized liquid polybutadienes

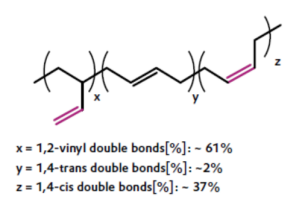

POLYVEST® MV - mid vinyl content, non-functionalized liquid polybutadiene

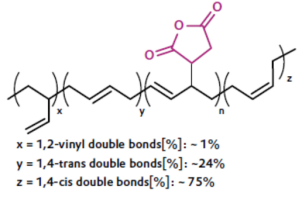

POLYVEST® MA75 - maleic anhydride-functionalized liquid polybutadienes

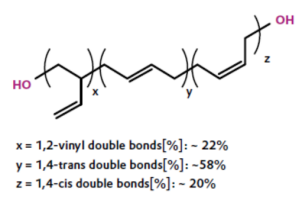

POLYVEST® HT- hydroxyl-terminated liquid polybutadiene

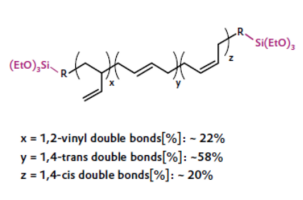

POLYVEST® ST- silane-terminated liquid polybutadiene

POLYVEST® EP MAT- methacrylate-terminated liquid polybutadiene

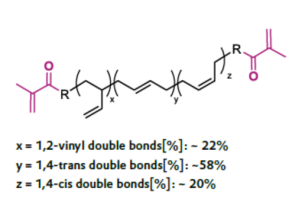

| Product Range | ANALYTICAL METHODS | ||||||||

| POLYVEST® | 110 | 130 | EP* MV | MA 75 | EP* MA 100 | HT | ST-E 60 | EP* MAT | Viscosity Determination according to DIN EN ISO 3219. |

| Specifications | Acid Number Determination according to DIN EN ISO 2114. |

||||||||

| Viscosity at 20°C [mPa s] | 700-860 | 2,700-3,300 | 5,000- 7,000 | 6,000-9,000 | - | - | 7,500-15,000 | 6,000-9,000 | Hydroxyl Number Determination according to DIN 53 240-2. |

| Viscosity at 30°C [mPa s] | - | - | - | - | 10,000-16,000 | 4,000-5,500 | - | Peroxide Number Determination according to DGF-method: C-VI-6a (84). |

|

| Acid Number [mg KOH/g] | ≤0.3 | ≤0.3 | ≤0.5 | 70-90 | 95-115 | - | - | Iodine Number Determination according to DIN 53 241. |

|

| Hydroxyl Number [mg KOH/g] | - | - | - | - | - | 44-51 | - | Molecular Weight, Mn Determination via GPC according to DIN 55 627-1, calibrated either with polystyrene or polybutadiene standards (please see footnote for details) |

|

| Peroxide Number [mval/kg] | ≤10 | ≤10 | ≤10 | - | - | - | - | Density Determination according to DIN ISO 2811-1 (at 20°C). Determination according to DIN 51757, method 4 (at 25°C). |

|

| Water Content [mg /kg] | - | - | - | - | - | - | ≤500 | - | Flash Point Determination according to DIN EN ISO 2719. |

| Gardner Color - | - | - | - | ≤2.5 | - | - | ≤1.5 | - | Gardner Color Determination according to DIN EN ISO 4630. |

| Typical Data | Ignition Temperature Determination according to DIN 51 794. |

||||||||

| Molecular Weight,Mn [g/mol]** | approx.2,600** | approx.4,600** | approx.2,900** | approx.2,900** | approx.3,100 | approx.2,900*** | approx.3,200*** | approx.3,000*** | Pour Point Determination according to DIN ISO 3016. |

| Iodine No. [g lod/100g] | 420-480 | 420-480 | approx.400 | 380-420 | 350-390 | 420-440 | - | - | Glass Transition Temperature, Tg Determination according to DIN EN ISO 11 357-1. |

| Density at 20°C [g/cm³] | 0.90-0.92 | 0.90-0.92 | 0.89-0.92 | approx.0.95 | approx. 0.96 | 0.90-0.92 | 0.8 -1.0 at 25°C | - | Water Content Determination according to DIN 51777-2. |

| Gardner Color - | ≤1 | ≤4 | ≤1 | - | ≤3.0 | ≤1 | - | approx.6 | Residue on Ignition at 950°C Determination according to ASTM D 6740. |

| Flash Point [℃] | approx.180 | approx.200 | >245 | approx.300 | approx.260 | approx. 215 | - | - | |

| Ignition Temperature [℃] | approx.360 | approx.350 | approx.360 | approx.360 | approx.375 | approx. 375 | - | - | |

| Pour Point [°c] | approx.-55 | approx.-50 | approx.-27 | approx.-25 | approx.-18 | approx. -18 | - | - | |

| Glass transition Temperature, Tg [℃] | approx.-102 | approx.-104 | approx.-70 | approx.-95 | approx.-100 | approx.-80 | approx.-80 | approx.-83 | |

| Mean functionality - | - | - | - | - | - | approx.2.4(-OH) | approx. 1.5(Silane) | 2.4(Methacrylate) | |

| Residue on Ignition at 950°C [wt.%] | - | - | - | - | - | - | 1.0 -3.5 | - | |

| Note: all POLYVEST® grades are supplied in liquid viscous form. | |||||||||

| * EP = Experimental Product. The indicated properties are target values and may be subject to change during the upscaling process. | |||||||||

| ** = Determination via GPC calibrated with polystyrene standard. | |||||||||

| *** = Determination via GPC calibrated with polybutadiene standard. | |||||||||